McFlusion offers modular, customized, process cleaning (CIP/COP) and sterilization (SIP) equipment that are engineered, manufactured, tested and qualified in our facility prior to delivery.

Our process cleaning & sterilization equipment are designed for efficient performance, lean operation and to meet cGMP and GAMP requirements that govern the life science, pharmaceutical and specialty food industries. Our systems are available with various automation, integration, QA and Qualification packages.

Each system is fabricated using our Project Quality System (PQS) as well as our highly skilled craftsmen, which enables us to manage and control the quality of the manufacturing at the source - thereby, we are not relying exclusively on final inspection & QA control of the finished system. This allows effective control of schedule, quality and costs.

Our CIP/SIP equipment program includes, but is not limited to, the following:

CSV-series - CIP/SIP equipment for Biotech and Biopharm

Modular, decentralized, CIP/SIP equipment for high-end cGMP drug manufacturers within sterile, vaccine and biotech industry segments - providing full TACCT performance, maximum process control as well as advanced monitoring and batch reporting that support dynamic validation.

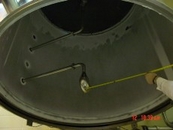

M-CAB - Washer & Dryer Systems for Parts and Bins

Modular cleaning & drying systems for biopharm, solid (oral) dosage form, chemical API and cosmetics facilities - designed for versatile cleaning and drying operations on a multitude of different process equipment, such as bins, drums, utensils and disassembled filling equipment.

The M-CAB platform supports seamless integration with McFlusion's stationary and portable CIP and CIP/SIP equipment.

Portable Carts w/ integrated Racks

Customized, specialty engineered, portable carts with integrated single or multi-layer racks and automatic distribution valves as well as static and/or dynamic spray devices for optimal cleaning of parts, such as disassembled filling equipment.

Racks support seamless integration with McFlusion's M-CAB washing & drying systems.