Material Handling Systems is a manufacturers' representative organization who has specialized in providing manufacturing equipment to the pharmaceutical industry since 1996. We generally cover the northeast to east coast of the USA. From start to finish, we have aspects of the manufacturing process covered: weigh and dispense, material handling, blending, milling, containment, sifting, compaction, granulation, continuous manufacturing, vacuum conveying, CIP/SIP, and more. We are currently representing:

Creative Design & Machine Inc. has been globally serving, designing and manufacturing blending and material handling equipment to Pharmaceutical, Food and Vitamin industries for over 30 years earning a reputation for quality and customer satisfaction. A complete list of references can be furnished upon request.

Our manufacturing facility is designed to meet and exceed the increasing demand for state-of-the-art equipment. All CDM equipment is manufactured by Creative Design & Machine in the United States at our New York facility. The after sales support we provide assures that if in the event you require service, we will be there. Our many years of experience assures your equipment shall be designed and manufactured with the standards you as a customer require.

We are market leaders in powder containment and aseptic transfer valves providing operator safety and sterility assurance for the pharmaceutical, biotech, chemical and other process industries. Over 20 years experience working with branded, generics and contract manufacturers to ensure both product quality and operator protection objectives are met while handling pharmaceutical ingredients in API and solid dose production.

ChargePoint® patented split valve technology offers improved sterility assurance in the aseptic processing of small components and powder product in fill/finish processes and during sterile API manufacturing. ChargePoint® split valves ensure manufacturers meet stringent safety requirements for dust control whilst transferring bulk powders during the production and handling of speciality, base and fine chemicals.

Extract Technology is a leading supplier of containment and aseptic systems for the pharmaceutical, biotech and nuclear industries. Our well-established product line includes isolators for containment of potent compounds and aseptic processing applications; Extract Technology brand downflow booths for operator protection from breathable dusts; and a full range of Extract Technology brand pack-off systems to safely offload powder products into drums or IBCs. Restricted Access Barrier Systems (RABS) are also available, providing unidirectional airflow and limited operator access at a manufacturing process. We will custom design equipment to best suit your process or integrated equipment needs.

Our Mobile Clean Room (MCR) provides fast, flexible clean room manufacturing space without the considerable time and costs associated with more traditional clean room options. The MCR can be designed with ISO 7 or ISO 8, BSL1 and BSL2+ environments for pharmaceutical and biotech applications, or ISO 5 and ISO 6 environments for semiconductor applications. The MCR is delivered fully assembled to your facility ready to use. Extended-width units are available to increase manufacturing space.

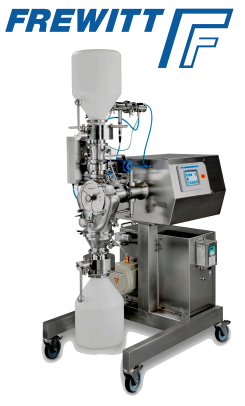

Frewitt manufactures competitively priced, robust, high-quality Milling and Sieving Equipment including Hammer Mills, Oscillating Mills, Conical Sieve Mills (i.e.: "cone mill"), Turbo Sifters, Crushers, and Lump Breakers. Our areas of expertise include systems for cGMP / WIP / SIP / Highly Contained Units for low OEL requirements and or low MIE applications that require nitrogen inerting.

Although Frewitt has been in business since 1946, our US headquarters was established in 2013 to better serve our Frewitt customers in North America. Our NJ facility includes a test / demo lab and stocks spare parts as well. Our modular mill design (ie: “FreDrive”) really differentiates us in the marketplace. The FreDrive platform has the feature of interchangeability of milling heads. We offer the FreDrive from lab / bench top to production size units. It could be supplied complete with Heads for a hammer mill, conical sieve mill, and or a rotary sifter / mill. This obviously offers the best value for the money and allows you the ability to perform three different processes in one mill platform: fine milling, de-agglomeration, and rotary sifting.

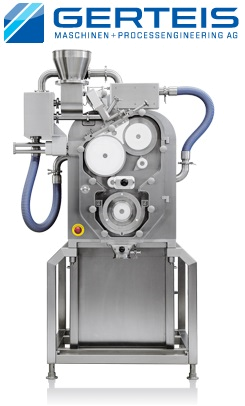

GERTEIS MASCHINEN + PROCESSENGINEERING AG had its beginnings as a one-man enterprise in Jona, Switzerland where the corporate headquarters is located to this day. Throughout the years the company grew exponentially and established itself as the market leader for premium dry granulation equipment.

With our focus on roller compactors, we pride ourselves in possessing an in-depth knowledge on all aspects of dry granulation and the related processes which is much to the benefit of our customers.

With its innovative technological capabilities for design, development, manufacturing and process optimization, GERTEIS guarantees the optimal solution for your dry granulation needs.

The company was established in 1986 and is headquartered in Jona, Switzerland, ever since. GERTEIS specializes in design, development and production of premium roller compactors for the pharmaceutical, chemical and food industry.

McFlusion is a highly specialized life-cycle supplier of advanced processes and equipment solutions for cleaning (CIP) and sterilization (SIP) as well as a wide array of cleaning related services to the FDA regulated life science, pharmaceutical, brewery and specialty food industries.

At McFlusion, we specialize in providing innovative technology solutions and quality craftmanship - we develop the best, most pragmatic, and sustainable process solutions, source the right equipment and components as well as manage project deliverables from A-Z - making sure that you are satisfied with the outcome. We are recognized as experts within our field, and through our extensive process knowledge and practical experiences we assist you in understanding and developing the best possible solutions to meet your specific challenges and needs. We consider each project a continuous close partnership with you, and will actively strive to earn your trust and confidence every day by offering value added, high quality, services and equipment.

3V Tech is a leading provider of advanced Process Solutions & Process Equipment, specializing in Specializing in Filters, Filter-Dryers, Vacuum Dryers, Thermal Separation & Glasslined Equipment.

By combining process and engineering know-how with its manufacturing capabilities, 3V Tech positions itself in the market of advanced process solutions and process equipment. The company avails two design and manufacturing sites, with a total covered surface in excess of 16.000 m2 and operates its own 2,000 m2 testing facility where pilot plant trails can be carried.

3V TECH USA Inc is a wholly-owned subsidiary of 3V TECH Equipment & Process Systems SpA in Italy, and is a fully integrated supplier of technology, equipment, solutions and systems for the chemical, pharmaceutical and environmental industry. One year ago we incorporated 3V TECH USA Inc and we completed our new 3V TECH USA facility in Andrews, SC near our Georgetown, SC headquarters, with full glasslining and refurbishing capabilities. Our mission in 3V TECH USA Inc is to become a first class service and customer oriented American company leveraging the technological know how and expertise of the 3V Group and offering:

COGEIM® equipment and refurbishment of any brand of filter dryers, paddle dryers, conical dryers

MABO® equipment and refurbishment of thin film, wiped film or short path evaporators

GLASSCOAT® Glass-lined vessels as well as reglassing of vessels